In industries like recycling, mining, and design, equipment need to be challenging and dependable. Products for instance a trommel, crushers, and shredders help separate, approach, and lower products. To keep these machines Functioning adequately, it’s crucial to learn about the key elements and whenever they might require changing.

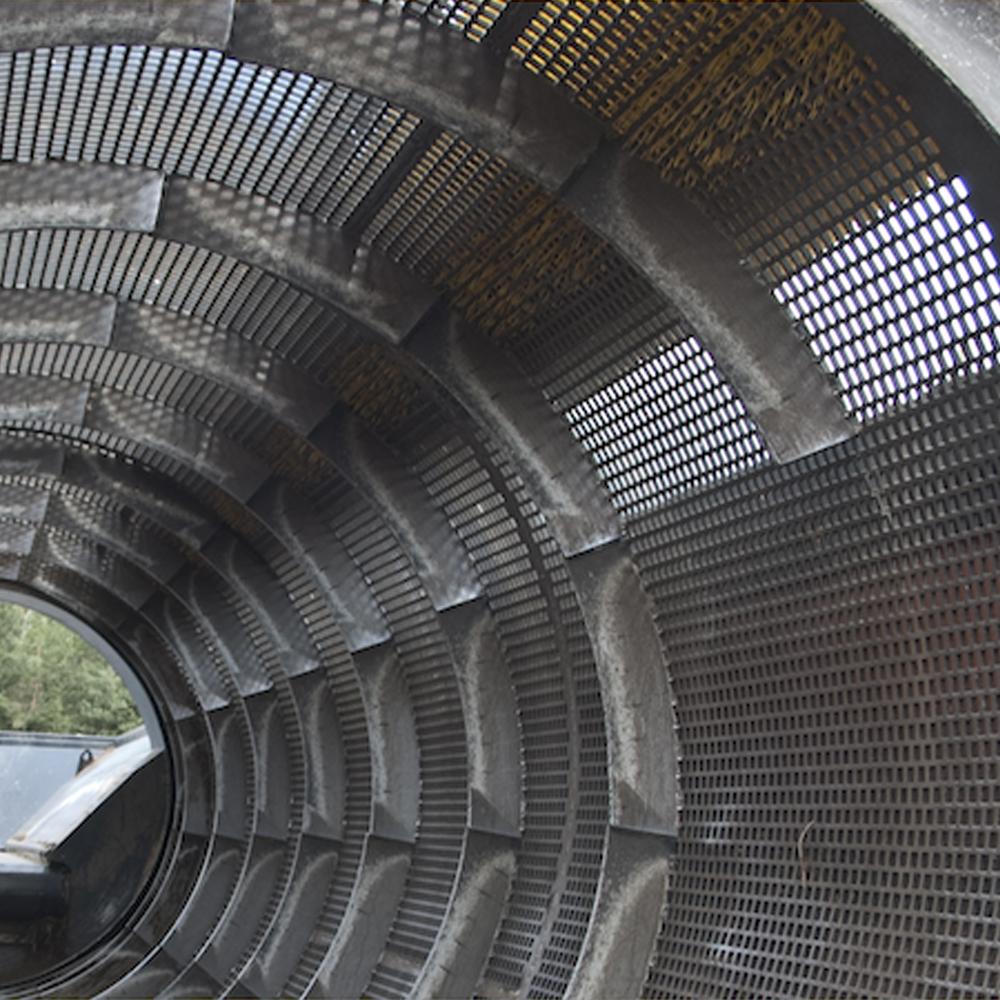

What on earth is a Trommel Drum?

A trommel drum is a significant rotating cylinder with holes that separates products by sizing. Such as, in recycling, it kinds waste into smaller sized and larger parts.

In mining, it helps separate rocks and minerals. The drum needs to be strong mainly because it handles significant masses each day.

Keeping Crushers in Superior Form

Crushers are used to stop working rocks, concrete, or waste into smaller parts.

With time, the parts crusher like jaws, liners, and hammers wear out as a consequence of consistent impact.

Changing worn elements on time would make positive the equipment continues to operate safely and successfully.

Why Screening Components Make any difference

Screening machines individual supplies into unique sizes, similar to a trommel but with flat or angled screens.

The screening parts must in shape correctly and be rough sufficient to manage sharp or major components.

Solid screens mean far better general performance and less downtime for repairs.

Shredder Elements for Weighty Responsibility Work

Shredders Lower by Wooden, metallic, plastic, or squander materials.

Their blades and cutters confront a great deal of tension every day.

That’s why shredder parts should be replaced routinely to help keep the device reducing cleanly.

Using the proper spare elements keeps shredders working easily for more time.

How to Extend Machine Lifestyle

Normal checks and upkeep create a large distinction.

Easy actions like cleaning, greasing going sections, and changing worn-out elements early can get monetary savings Over time.

Selecting parts from the trustworthy supplier makes sure excellent and sturdiness.

Final Views

Irrespective of whether it’s a trommel, crusher, screener, or shredder, just about every machine depends on sturdy and dependable pieces.

By using the right parts and keeping up with routine maintenance, firms can reduce breakdowns and retain manufacturing running efficiently.

Buying good quality parts is usually a sensible choice for very long-term effectiveness.